The first two posts in our Water Series focused on steaming. This last post looks at water conservation in hot produced-water thermal recovery.

PART 3: “Hot Produced Water – Eliminating fresh water usage”

Our Direct Contact Steam Generation (DCSG) technology can be used to produce hot water (and flue gases) instead of steam (and flue gases).

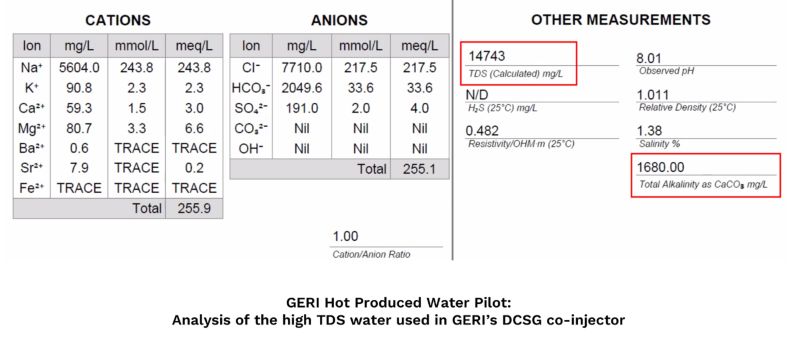

When producing hot water (and flue gases), our DCSG co-injector can use high TDS reservoir water as a feed-stock, which is an ideal thermal solution for reservoirs containing fresh water sensitive clays and/or in areas with fresh water constraints.

By using produced water, we remove the need to draw on any additional (fresh) water source.

GERI’s DCSG co-injector has successfully heated produced water on two occasions using 14,000 and 30,000 ppm TDS water, without any significant scaling issues, at rates up to 240 m3/d. The expected maximum injection rate is 400 m3/d (with slight modification of the current equipment), at a temperature up to boiling point (dependant on injection pressure).

In addition to the environmental benefits of eliminating fresh-water usage, utilizing saline reservoir water also removes the financial burden of procuring alternative/fresh water sources and can offer significant costs savings on the trucking/disposing of produced water.