“WHAT ARE THE CORROSION CONCERNS WHEN INJECTING FLUE GAS AND STEAM?”

It’s a great question and one we often get asked, so we thought we’d answer it here too.

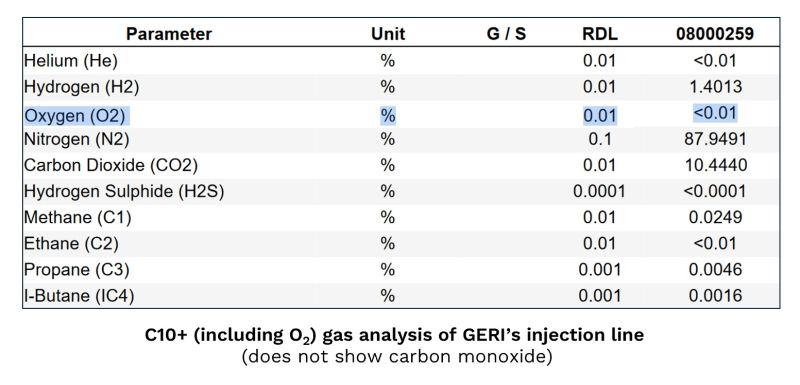

Corrosion is something we pay close attention to, and corrosion analyses (XRD) on coupons from some of our earlier pilots indicated that CO2 was not the major contributor to corrosion, O2 was. Through iterative design and operational improvements, GERI has been able to almost completely eliminate O2 in the injection stream, to as low as <100 ppm in the vapour phase, substantially reducing corrosion.

Additionally, through proper material selection of commonly available tubulars, GERI has been able to reduce corrosion to a level that is entirely manageable.

GERI also has an ongoing corrosion coupon monitoring program and is equipped to inject a corrosion inhibitor or oxygen scavenger as additional protection.