Today is World Water Day 2024 💦, so the perfect day to post the second installment of our Water Series! In this post, we explain how improved efficiency in oil recovery reduces water requirements.

PART 2: "Steaming – Reducing water usage through improved Steam-to-Oil Ratio (SOR)"

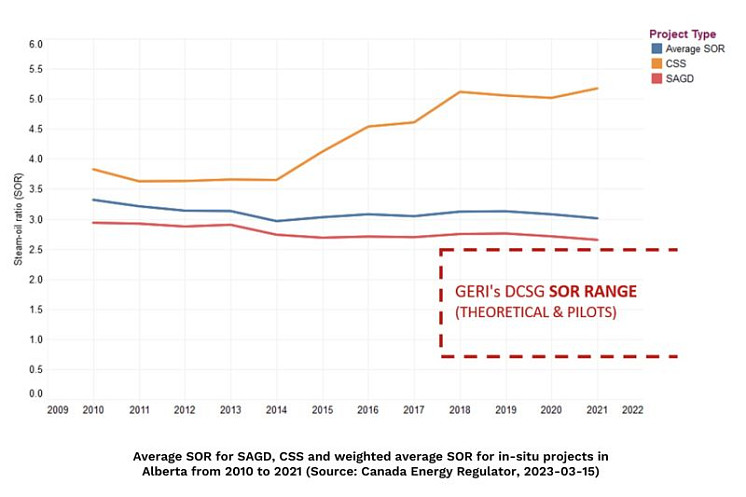

In the oil industry, the Steam-to-Oil Ratio (SOR) is the ratio of steam volume injected (in cold-water-equivalent (CWE)) in relation to the volume of oil produced (m3/m3).

With Direct Contact Steam Generation (DCSG), the added benefits of co-injecting steam with flue gases (e.g. pressurization from non-condensable flue gases & reduction in viscosity due to the CO2) result in a lower SOR. The lower the SOR, the less water is required to produce the oil.

The average SOR for Alberta thermal in-situ CSS & SAGD projects is 3.0 (source: Canadian Energy Regulator, 2023.03.15), generally ranging from 2 to 5. By contrast, GERI’s DCSG pilot projects have resulted in a SOR as low as 0.6, meaning that DCSG can significantly reduce the water requirements compared to conventional thermal.