Many legacy wells drilled into reservoirs suitable for thermal EOR are not thermally completed or inadequately thermally completed. In such cases, injecting steam exposes the casing and cement to elevated temperatures which is almost certain to cause irreparable damage to the well. This makes thermal recovery of vast quantities of easy-to-access oil a challenge.

GERI’s CasingCooler™ “makes steaming possible” by allowing the thermal stimulation of non-thermally completed wells and inadequately thermally completed wells.

The CasingCooler™ is a patent-pending system that protects the well casing and cement from elevated temperatures during thermal stimulations by continuously circulating coolant between the vacuum insulated tubing (VIT) and the well casing.

View Full Image

Easy and

quick installation.

Re-usable (can be quickly

deployed to other wells).

Low power

requirements

Delivery time of 2-3

months for new units.

Fully automated controls

making it easy to operate.

Closed loop circulating system

meaning no additional water requirments.

Very small

surface footprint

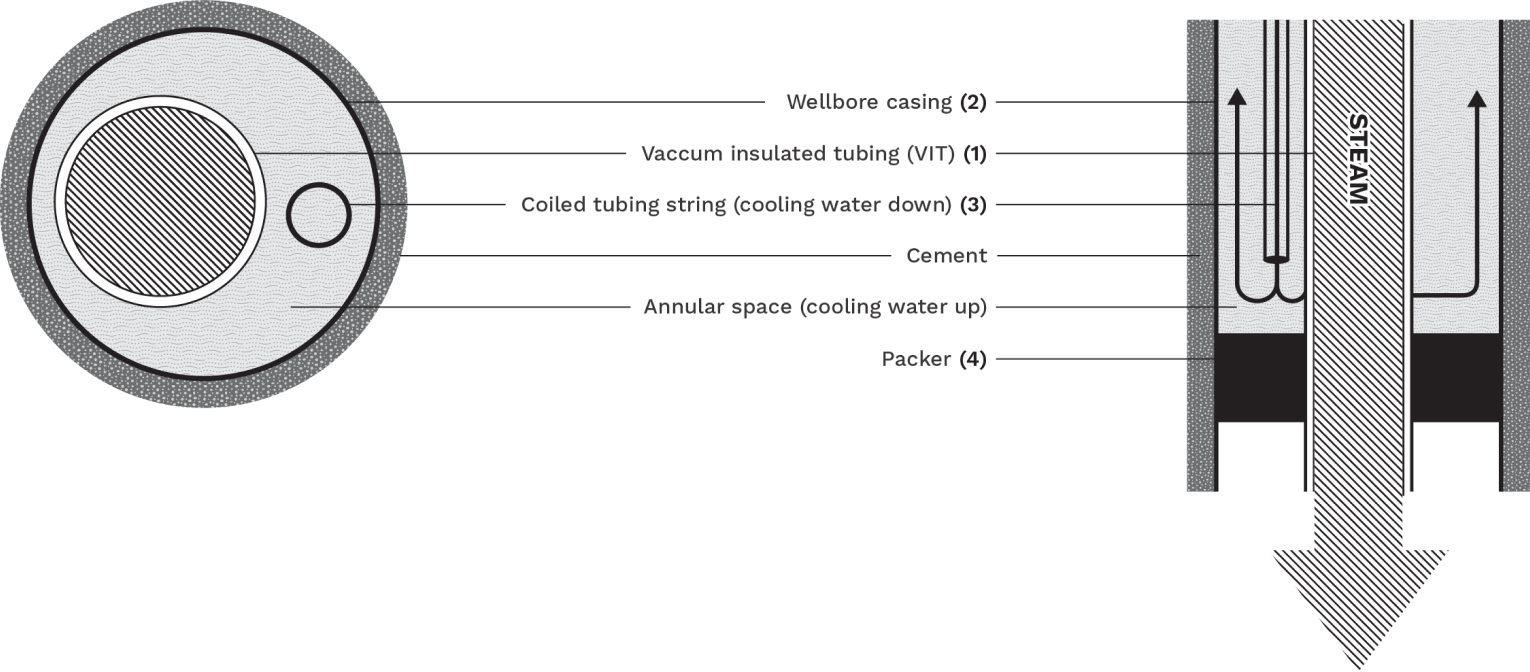

In thermal well operations, high temperature fluids (typically steam) are injected into a well, normally down tubing (1) inserted inside the wellbore casing (2).

The CasingCooler™ configuration involves installing a custom injection packer seal (4) just above the injection zone to isolate and protect the casing above the packer. Acoiled tubing string (3) is inserted in the annular space (the area between the outside the VIT and the inside of the casing), terminated just above the top of the packer.

Corrosion-inhibited coolant water is pumped at low-pressure and low-rate down the coiled tubing (3) which exits at the custome packer (4) top. The water then flows back to surface within the annular space between the tubing and casing, protecting the casing from elevated tempereature. The coolant water returns to surface, is cooled in a heat exchanger, and is then stored in a tank, ready for reinjection.

CASINGCOOLER™ HORIZONTAL CROSS SECTION

CASINGCOOLER™ VERTICAL CROSS SECTION

The system is designed to be inherently safe, using automatic controls/shut-down and constant, real time temperature, pressure and volumetric (tank levels) measurements, enusuring proper and safe operation. The system can be viewed and controlled remotley.

The CasingCooler™ been independently scrutinized through robust and rigrous hazard and operability analyses (HAZOP) and has been used successfully in two different Canadian regulatory jurisdictions.

The CasingCooler™ system is very flexible and is deployable in a wide variety of applications. GERI has developed a heat-transfer model to determine customer well-specific CasingCooler™ design and configuration

CasingCooler™ Thermal Circuit

View Full Image

The CasingCooler™ is flexible in the type of cooling fluid that can be used; however, we recommend using fresh inhibited water.

Yes. GERI uses a custom heat-transfer model to determine the required radiator size and circulation rates/temperatures to protect the wellbore.

With the use of vacuum insulated tubing (VIT), very little heat is lost to the annulus. Depending on the application, the heat lost is <3%